As How to Understand the Difference Between Pans and Tubes takes center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

Navigating the distinct realms of culinary tools and scientific apparatus can sometimes lead to moments of confusion. This exploration is designed to illuminate the fundamental distinctions between “pans” and “tubes,” clarifying their unique characteristics, applications, and the underlying principles that govern their design and function.

Defining “Pans” in a Culinary Context

In the realm of cooking, a “pan” is a fundamental piece of cookware designed for a multitude of culinary tasks. These versatile vessels are engineered to facilitate direct heat transfer, enabling us to sauté, fry, simmer, boil, and bake. Understanding the nuances of different pans is key to achieving optimal results in the kitchen, transforming raw ingredients into delicious meals.Pans are distinguished by their construction materials, shapes, sizes, intended functions, compatible heat sources, and specific features.

Each element plays a crucial role in how heat is distributed and managed, directly impacting the cooking process and the final outcome of a dish.

Common Materials Used in Pan Construction

The materials used to craft cooking pans significantly influence their performance, durability, and suitability for various cooking methods. Different materials offer unique heat conductivity, retention, and reactivity properties, making some pans better suited for specific applications than others.

- Stainless Steel: A popular choice due to its durability, non-reactivity with acidic foods, and ease of cleaning. It often features an aluminum or copper core for improved heat distribution.

- Cast Iron: Known for its exceptional heat retention, cast iron pans become increasingly non-stick with proper seasoning. They are ideal for searing and slow cooking but require careful maintenance to prevent rust.

- Copper: Offers superior heat conductivity, allowing for precise temperature control. Copper pans are often lined with stainless steel or tin to prevent reactivity.

- Aluminum: Lightweight and an excellent conductor of heat, aluminum pans are often used with non-stick coatings. Anodized aluminum is more durable and less reactive.

- Non-stick Coatings: Materials like PTFE (Teflon) or ceramic are applied to the cooking surface to prevent food from sticking, making cooking and cleanup easier.

Typical Shapes and Sizes of Pans

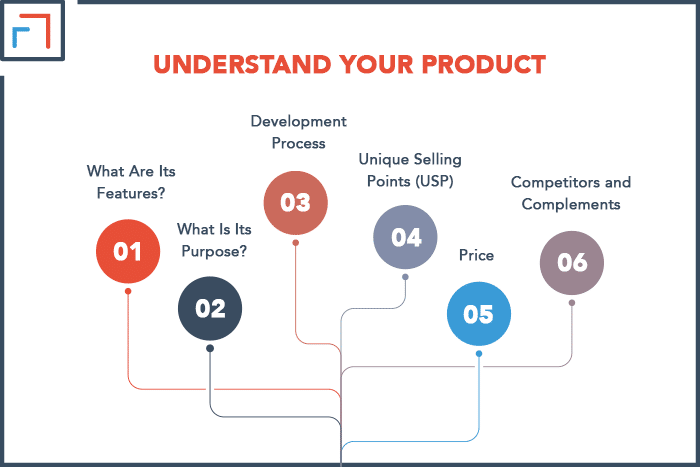

The diverse array of cooking tasks necessitates a variety of pan shapes and sizes, each optimized for specific culinary purposes. From delicate sauces to large roasts, the appropriate pan ensures even cooking and efficient preparation.The following table illustrates common pan types, their typical dimensions, and their primary uses:

| Pan Type | Typical Diameter/Dimensions | Common Uses |

|---|---|---|

| Frying Pan/Skillet | 8-12 inches | Searing, frying, sautéing, browning |

| Saucepan | 1.5-4 quarts | Simmering sauces, boiling liquids, cooking grains |

| Stockpot/Dutch Oven | 6-12 quarts | Soups, stews, braising, boiling large quantities |

| Sauté Pan | 10-12 inches | Sautéing with higher sides to prevent splattering |

| Wok | 14-16 inches (diameter) | Stir-frying, deep-frying, steaming |

Primary Functions and Purposes of Different Pan Types

Each type of pan is meticulously designed to excel at specific cooking techniques, contributing to the versatility and efficiency of a well-equipped kitchen. Understanding these distinctions is crucial for selecting the right tool for any given recipe.

- Frying Pan/Skillet: Characterized by its wide, flat bottom and gently sloping sides, the frying pan is ideal for achieving a good sear on meats, frying eggs, and sautéing vegetables. The large surface area allows for quick evaporation of moisture.

- Saucepan: Featuring high, straight sides and a smaller diameter, saucepans are designed to hold liquids. They are perfect for making sauces, reducing liquids, boiling water for pasta, and cooking grains like rice or quinoa.

- Stockpot: The largest of common pans, stockpots have tall, straight sides and a broad base. They are essential for making large batches of stocks, broths, soups, stews, and for boiling large items like corn on the cob or lobsters.

- Sauté Pan: Similar to a frying pan but with taller, straighter sides, the sauté pan is excellent for cooking foods that require higher heat and for dishes where ingredients might splash out of a traditional skillet. It allows for both sautéing and simmering.

- Wok: A traditional Asian cooking vessel with a rounded bottom and high, sloping sides, the wok is designed for high-heat cooking methods like stir-frying. Its shape allows for ingredients to be tossed and moved easily, ensuring even cooking.

Heat Sources Pans Are Designed to Work With

The design and material of a cooking pan are intrinsically linked to the type of heat source it is intended to be used with, ensuring safety, efficiency, and optimal cooking performance. Using a pan on an incompatible heat source can lead to poor cooking results, damage to the cookware, or even safety hazards.

Most pans are designed for:

- Stovetop: This includes gas, electric coil, smooth-top electric, and induction cooktops. Pans made of materials like stainless steel, cast iron, and copper with a flat bottom are generally suitable for most stovetops. Induction cooktops require pans with magnetic bases.

- Oven: Many pans, especially those made of cast iron, stainless steel, or oven-safe non-stick materials, can be safely transferred from the stovetop to the oven. This is crucial for techniques like searing a steak on the stovetop and finishing it in the oven.

It is always important to consult the manufacturer’s recommendations for specific cookware to ensure compatibility with your heat sources.

Features Distinguishing One Type of Pan from Another

Beyond their basic shape and material, a variety of specific features differentiate cooking pans, enhancing their functionality and user experience. These details often dictate the best use for a particular pan and contribute to its overall effectiveness in the kitchen.

- Handles: Pan handles vary in length, material (e.g., stainless steel, silicone, wood), and attachment method (riveted, welded). Longer handles provide better leverage and keep hands away from heat, while ergonomic designs offer comfort. Some pans feature helper handles for added support when lifting heavy loads.

- Lids: The presence and type of lid are significant. Lids trap heat and moisture, which is essential for simmering, braising, and boiling. Materials can range from glass (allowing visibility) to solid metal. Some lids have steam vents to prevent over-pressurization.

- Non-stick Coatings: As mentioned earlier, these coatings are applied to facilitate easy food release and simplify cleaning. The type and durability of the non-stick coating are key distinguishing factors, with some being more resistant to scratching and high heat than others.

- Wall Height and Slant: The height and angle of a pan’s walls directly influence its intended use. High, straight walls are for containment (saucepans, stockpots), while lower, sloped walls are for easy access and flipping (frying pans).

- Base Thickness and Construction: A thicker, well-constructed base ensures even heat distribution and prevents hot spots, which can lead to uneven cooking and scorching. Pans designed for induction cooktops will have a magnetic material integrated into their base.

Defining “Tubes” in a Scientific and Technical Context

In scientific and technical disciplines, the term “tube” refers to a hollow cylinder designed for the conveyance of fluids (liquids or gases), for the passage of light, or as a structural component. Unlike their culinary counterparts, scientific and technical tubes are characterized by precision in their dimensions, material properties, and intended function, often serving critical roles in experimentation, manufacturing, and instrumentation.The fundamental concept of a tube in these fields is its hollow nature, allowing for flow or transmission.

This hollow core is enclosed by a solid wall, which provides structural integrity and defines the tube’s external characteristics. The specific design and material selection are paramount, as they dictate the tube’s performance under various conditions, including pressure, temperature, chemical exposure, and electrical conductivity.

Common Materials for Tube Manufacturing

The selection of material for a tube is a critical decision driven by the intended application and the environmental conditions it will encounter. Different materials offer distinct advantages in terms of durability, inertness, transparency, and cost.A variety of materials are commonly employed in the manufacturing of tubes for scientific and technical applications:

- Glass: Borosilicate glass, such as Pyrex, is widely used due to its excellent chemical resistance, thermal shock resistance, and transparency. It is ideal for handling corrosive substances and for visual observation of processes.

- Metals: Stainless steel, copper, brass, and aluminum are frequently used. Stainless steel offers high strength, corrosion resistance, and durability, making it suitable for high-pressure applications and vacuum systems. Copper and brass are excellent conductors of heat and electricity, often used in heat exchangers and electrical components. Aluminum is lightweight and corrosion-resistant, finding use in various structural and fluid conveyance systems.

- Plastics: A broad range of polymers, including PVC, polyethylene, PTFE (Teflon), and silicone, are utilized. These materials offer flexibility, electrical insulation, chemical inertness, and cost-effectiveness. PTFE is particularly valued for its extreme chemical resistance and low friction properties. Silicone is favored for its flexibility and biocompatibility, often used in medical devices.

Applications of Tubes in Laboratory and Industrial Settings

Tubes are ubiquitous in scientific research and industrial processes, serving a multitude of essential functions that enable complex operations and precise measurements. Their versatility makes them indispensable across diverse fields.The applications of tubes are extensive and can be broadly categorized as follows:

- Fluid Conveyance: This is perhaps the most common application, where tubes are used to transport liquids, gases, or slurries between different points in a system. Examples include plumbing in chemical plants, blood lines in medical equipment, and delivery systems for reagents in laboratories.

- Instrumentation: Tubes are integral components of various scientific instruments. For instance, they are used in chromatography columns to separate chemical compounds, in mass spectrometers to guide ions, and in optical systems as light guides or beam paths.

- Heating and Cooling: In heat exchangers, tubes are designed to facilitate efficient transfer of thermal energy between fluids. This is crucial in power generation, refrigeration, and chemical processing.

- Structural Support: In some instances, tubes are employed for their structural properties, providing lightweight yet strong frameworks for equipment or apparatus.

- Vacuum Systems: Tubes made of robust materials like stainless steel or specialized glass are essential for creating and maintaining high vacuum environments in research and manufacturing.

Key Characteristics Defining Tube Function

The performance and suitability of a tube for a specific task are determined by a combination of its physical dimensions and the inherent properties of the material from which it is made. These defining characteristics are meticulously considered during the design and selection process.The following key characteristics are crucial in defining a tube’s function:

- Diameter: Both the internal (bore) and external diameters are critical. The internal diameter dictates the volume of fluid that can pass through and influences flow rate. The external diameter affects how the tube fits into other components or systems.

- Length: The length of the tube influences factors such as pressure drop due to friction, the time it takes for a fluid to travel through it, and the overall footprint of the system.

- Wall Thickness: This directly impacts the tube’s strength and its ability to withstand internal or external pressure. Thicker walls generally provide greater structural integrity and resistance to deformation or rupture.

- Material Properties: These encompass a wide range of attributes including:

- Chemical Inertness: Resistance to corrosion or reaction with the substances being conveyed.

- Temperature Resistance: The ability to maintain structural integrity and performance across a specified temperature range.

- Mechanical Strength: Resistance to bending, crushing, or tensile forces.

- Transparency: For applications where visual monitoring is required.

- Electrical Conductivity/Insulation: Depending on whether the tube is intended to conduct or prevent electrical current.

Methods for Shaping and Forming Tubes

The creation of tubes with precise dimensions and specific shapes is achieved through a variety of manufacturing processes. These methods are chosen based on the material, desired tolerances, and the complexity of the final form.Various techniques are employed to shape and form tubes for their intended purposes:

- Extrusion: This process involves forcing a material through a die of a specific cross-section. It is commonly used for plastics and metals to create seamless tubes with consistent dimensions. For metals, hot extrusion is often employed, where the material is heated to a malleable state before being pushed through the die.

- Drawing: In this method, a pre-formed tube is pulled through a die or over a mandrel. This process reduces the diameter and wall thickness, improves surface finish, and enhances dimensional accuracy. It is frequently used for metals and glass.

- Rolling: For larger diameter metal tubes, processes like roll forming or seamless pipe rolling are used. In seamless pipe rolling, a solid billet is pierced and then rolled to form a hollow tube.

- Molding: For certain plastic tubes, particularly those with complex cross-sections or integrated features, injection molding or blow molding techniques can be utilized.

- Bending and Machining: After initial forming, tubes can be further shaped by bending them to specific angles, often using specialized machinery to prevent kinking or collapse. Machining processes like cutting, drilling, and flaring are also used to create custom fittings and connections.

Core Distinguishing Features

While both pans and tubes serve as vessels for containing substances, their fundamental physical forms, intended functions, and operational environments are remarkably distinct. Understanding these core differences is crucial for appreciating their specific roles in various applications, from the kitchen to advanced scientific research. This section will delve into these key distinguishing characteristics.The primary divergence between pans and tubes lies in their geometry and the purpose dictated by that geometry.

Pans are designed for broad containment and manipulation, often involving open surfaces for cooking or mixing, whereas tubes are engineered for directed flow, channeling, and precise containment of substances in a linear or confined manner.

Physical Forms

The physical form of a pan is typically characterized by a wide, open receptacle with a flat or gently curved bottom and raised sides. This design facilitates access for stirring, mixing, and exposure to heat or other environmental factors. In contrast, a tube is a hollow cylinder or a similarly shaped conduit, closed at the ends or connected to other components, designed to guide the passage of materials.

Key physical differences include:

- Pan Shape: Generally round, square, or rectangular with a significant open surface area. The depth is usually less than the width or length.

- Tube Shape: Primarily cylindrical, but can also be rectangular or other regular cross-sections. The defining feature is its hollow, elongated nature.

- Openings: Pans are characterized by a large, open top. Tubes have defined inlets and outlets for material flow.

- Wall Thickness: Pan walls are typically thinner and designed for heat transfer, while tube walls are often thicker and engineered for structural integrity and pressure resistance.

Primary Uses and Intended Functions

The intended functions of pans and tubes are directly derived from their physical forms. Pans are primarily used for cooking, baking, mixing, and displaying food, as well as for holding liquids or solids in a stable, accessible manner. Their open design allows for easy manipulation and exposure to heat or cooling. Tubes, on the other hand, are designed for the transportation, containment, and precise measurement or delivery of fluids, gases, or small solid particles.

They are integral to systems where controlled movement and isolation are paramount.

Comparing their functions:

- Pans: Facilitate cooking processes (e.g., frying, sautéing, boiling), baking (e.g., cake pans, baking sheets), mixing ingredients, and serving food.

- Tubes: Enable fluid transfer in plumbing and industrial processes, serve as conduits for electrical wiring, form structural components in engineering, and are used in scientific apparatus for reactions and analysis.

Typical Environments of Utilization

The environments where pans and tubes are commonly found reflect their respective functions. Pans are ubiquitous in kitchens, bakeries, laboratories (for certain types of experiments), and dining settings. Their use is closely tied to food preparation and presentation. Tubes, conversely, are prevalent in a much broader range of technical and scientific settings. They are essential components in:

- Industrial Plants: For transporting raw materials, finished products, and utilities like steam or water.

- Medical Facilities: In devices like IV lines, catheters, and respiratory equipment.

- Scientific Laboratories: For chemical reactions, fluid dynamics experiments, and analytical instrumentation.

- Construction and Infrastructure: As part of plumbing systems, ventilation, and structural elements.

- Automotive and Aerospace: For fuel lines, hydraulic systems, and exhaust components.

Common Measurement Units

The measurement units used for pans and tubes often differ, reflecting the nature of the items they are used to describe. For pans, measurements typically relate to their capacity, diameter, and depth, often using imperial or metric units for length and volume.

Common measurements for pans include:

- Diameter/Width/Length: Inches (e.g., 10-inch skillet), centimeters (e.g., 24 cm saucepan).

- Depth: Inches (e.g., 3-inch deep baking pan), centimeters (e.g., 8 cm depth).

- Capacity: Quarts (e.g., 4-quart stockpot), liters (e.g., 2-liter mixing bowl), cups.

For tubes, measurements are primarily concerned with their internal and external diameters, wall thickness, and length, which are critical for flow rate calculations, pressure ratings, and fitting compatibility.

Common measurements for tubes include:

- Internal Diameter (ID) / Bore: Millimeters (e.g., 10 mm ID tubing), inches (e.g., 1/4 inch bore).

- External Diameter (OD): Millimeters (e.g., 12 mm OD pipe), inches (e.g., 0.5 inch OD tube).

- Wall Thickness: Millimeters (e.g., 2 mm wall thickness), gauge (e.g., 16-gauge steel tubing).

- Length: Meters (e.g., 5-meter pipe), feet (e.g., 20-foot length of conduit).

- Schedule (for pipes): A system of nominal wall thickness related to diameter (e.g., Schedule 40, Schedule 80).

Typical Lifespans and Maintenance Requirements

The lifespan and maintenance requirements for pans and tubes are highly variable, depending on the materials they are made from, their intended use, and the environment they are exposed to.

Pans generally have lifespans that can range from a few years to several decades, with maintenance focused on cleaning and preventing damage.

- Materials: Stainless steel, cast iron, copper, and non-stick coated aluminum pans can last for many years with proper care.

- Maintenance: Regular cleaning to remove food residue, avoiding abrasive scrubbers that can damage coatings, and proper storage to prevent warping or scratching are typical. Cast iron requires seasoning.

- Lifespan Factors: Frequent high-heat use, exposure to harsh detergents, and physical damage can shorten a pan’s useful life.

Tubes, especially those in industrial or critical applications, are often designed for extended lifespans and may require more specialized maintenance.

- Materials: Metal pipes (steel, copper, aluminum), plastic tubes (PVC, PEX, silicone), and glass tubing have vastly different durability and lifespans.

- Maintenance: Can range from simple cleaning to regular inspections for leaks, corrosion, or wear. In some systems, flushing, pressure testing, or replacement of seals might be necessary.

- Lifespan Factors: The lifespan of a tube is significantly influenced by the pressure, temperature, and chemical nature of the substances flowing through it, as well as external environmental conditions. Corrosion, erosion, and material fatigue are common failure modes.

Practical Examples and Applications

Understanding the practical applications of pans and tubes solidifies their distinct roles. While pans are primarily designed for containing and manipulating substances, particularly in cooking, tubes excel at guiding, channeling, or forming structures. This section explores common examples to illustrate these differences vividly.Examining how these items are used in everyday life and specialized fields highlights their fundamental design principles and material considerations.

The choice of material, for instance, is crucial for both pans and tubes, directly impacting their functionality and longevity.

Culinary Pans and Their Diverse Uses

In the kitchen, a variety of pans are essential tools, each optimized for specific cooking techniques and ingredients. Their shapes, sizes, and materials are tailored to ensure even heating, prevent sticking, and facilitate manipulation of food.

The following table details common kitchen pans, their primary culinary applications, and the materials typically used in their construction:

| Pan Type | Primary Use | Material |

|---|---|---|

| Frying Pan (Skillet) | Searing, sautéing, frying, browning | Stainless steel, cast iron, non-stick coated aluminum |

| Saucepan | Simmering sauces, boiling liquids, reheating | Stainless steel, copper-bottomed, enamel-coated cast iron |

| Stockpot | Making stocks, soups, boiling large quantities | Stainless steel, aluminum |

| Baking Sheet (Cookie Sheet) | Baking cookies, roasting vegetables, dehydrating | Aluminum, steel |

| Wok | Stir-frying, deep-frying, steaming | Carbon steel, cast iron |

| Bundt Pan | Baking ring cakes | Aluminum, cast iron, silicone |

Tubes in Scientific and Technical Contexts

Tubes are ubiquitous in scientific and technical applications, serving as conduits for fluids, structural components, or measurement devices. Their cylindrical shape is key to their function, allowing for efficient flow, containment, or structural integrity.

The following examples showcase the diverse roles of tubes in everyday objects and scientific equipment:

- Plumbing: Water supply and drainage systems rely on a network of pipes (tubes) to transport water and waste.

- Medical Devices: Intravenous (IV) lines, catheters, and straws are all examples of tubes used for fluid transfer or support in medical settings.

- Straws: Simple drinking tubes that facilitate the transfer of liquids from a container to the mouth.

- Electrical Conduits: Protective tubes that house and shield electrical wiring.

- Scientific Instruments: Test tubes, pipettes, and chromatography columns are essential for chemical analysis and experimentation.

- Engines: Exhaust pipes and intake manifolds are tubes that manage gas flow in internal combustion engines.

- Pens and Markers: The ink reservoir in many writing instruments is a tube.

Material Influence on Performance

The materials from which pans and tubes are made significantly dictate their suitability for specific tasks. For pans, materials are chosen for their heat conductivity, distribution, and durability. For instance, cast iron pans excel at retaining heat for even searing, while stainless steel offers excellent durability and corrosion resistance. Non-stick coatings are applied to aluminum or stainless steel to prevent food from adhering.

For tubes, material selection is driven by factors such as chemical resistance, pressure tolerance, flexibility, and temperature stability. For example:

- Glass tubes are used in laboratories due to their chemical inertness and transparency, allowing observation of reactions.

- Metal tubes (like copper or steel) are used in plumbing and industrial applications for their strength and ability to withstand high pressures.

- Plastic tubes (like PVC or silicone) offer flexibility, chemical resistance, and cost-effectiveness for various applications, from garden hoses to medical tubing.

- Rubber hoses are chosen for their flexibility and ability to handle vibrations or significant expansion and contraction.

Scenario of Misapplication

Imagine attempting to use a large, shallow frying pan as a makeshift conduit for transporting hot oil in an industrial setting. The pan, designed to hold and distribute heat evenly for cooking, lacks the structural integrity and containment features of a proper pipe. The oil could easily spill over the sides, creating a significant fire hazard and potential for severe burns.

Conversely, trying to cook a delicate sauce in a narrow, rigid laboratory test tube would be impractical; the limited surface area and lack of control over heat distribution would likely result in scorching or uneven cooking, rendering the sauce unusable. These scenarios underscore how the fundamental design of pans for containment and even distribution, versus tubes for channeling and guidance, makes them unsuitable for each other’s primary roles.

Understanding Material Properties and Their Impact

The distinct functionalities of culinary pans and scientific/technical tubes are fundamentally rooted in the specific material properties employed in their construction. These properties dictate their performance, durability, and suitability for their intended applications, from the delicate balance of heat transfer in cooking to the rigorous demands of high-pressure environments.The choice of material significantly influences how a pan interacts with heat and food.

Different metals possess varying abilities to conduct heat, which directly impacts cooking speed, evenness of temperature, and the resulting quality of the cooked product.

Thermal Conductivity and Cooking Performance

Thermal conductivity is a critical property for cookware, determining how efficiently heat is transferred from the stovetop to the food. Materials with high thermal conductivity heat up quickly and distribute heat evenly, preventing hot spots that can lead to uneven cooking and burning.

- Copper: Exhibits exceptional thermal conductivity, heating rapidly and responding instantly to temperature changes. This makes it ideal for delicate sauces and precise temperature control, though it often requires a lining of stainless steel or tin for food safety and to prevent reactivity.

- Aluminum: Offers good thermal conductivity at a lower cost than copper. Anodized aluminum is particularly durable and less reactive. Cast aluminum is known for its excellent heat retention.

- Stainless Steel: While a poor conductor on its own, stainless steel is often used as an outer layer or in composite constructions (e.g., clad with copper or aluminum cores). This combination leverages the durability and non-reactivity of stainless steel with the superior heat conductivity of other metals.

- Cast Iron: Possesses excellent heat retention, meaning it stays hot for a long time once heated. However, it heats up slowly and can have uneven heating if not preheated properly. Its surface can also react with acidic foods.

Chemical Inertness and Substance Handling

In scientific and technical applications, the chemical inertness of materials used for tubes is paramount. This property ensures that the tube material does not react with, degrade, or contaminate the substances flowing through it, which is crucial for maintaining purity, safety, and the integrity of experiments or processes.

- Glass (e.g., Borosilicate Glass): Widely used due to its excellent chemical resistance to most acids, bases, and solvents. It is also transparent, allowing for visual monitoring of flow and reactions.

- Stainless Steel (e.g., 316L): A common choice for its corrosion resistance, particularly against a broad range of chemicals. It is durable and can withstand varying temperatures and pressures.

- PTFE (Polytetrafluoroethylene, e.g., Teflon): Known for its extremely low coefficient of friction and exceptional chemical inertness, resisting nearly all chemicals and solvents. It is often used in demanding applications where even minor reactivity is unacceptable.

- Certain Polymers (e.g., PEEK, PVDF): High-performance polymers are selected for their specific chemical resistance profiles, often offering advantages in flexibility or cost compared to metals or glass.

Structural Integrity for High-Pressure Applications

Tubes designed for high-pressure environments must possess superior structural integrity to prevent failure, leakage, or catastrophic rupture. This involves selecting materials with high tensile strength, yield strength, and resistance to fatigue under constant or fluctuating pressure.

- Materials: High-strength alloys, such as certain grades of stainless steel, titanium, or specialized nickel alloys, are often employed. The specific alloy selection depends on the operating pressure, temperature, and the chemical environment.

- Manufacturing Processes: Seamless tube manufacturing processes are preferred to eliminate potential weak points associated with welded seams. Techniques like cold drawing can further enhance the material’s strength and dimensional accuracy.

- Wall Thickness: The thickness of the tube wall is calculated based on the internal pressure, the material’s allowable stress, and a safety factor, ensuring it can withstand the intended pressure with a margin of error.

- Testing: Rigorous testing, including hydrostatic pressure testing and non-destructive examination methods (like ultrasonic testing or eddy current testing), is essential to verify the structural integrity of high-pressure tubes before deployment.

Heat Resistance Differences

The heat resistance of materials used in pans and tubes varies significantly, reflecting their distinct operational environments. Pans are designed to withstand direct and fluctuating heat from cooking sources, while tubes may be subjected to extreme temperatures as part of a process or simply to operate reliably within a broad thermal range.

- Pan Materials: Generally selected for their ability to conduct heat effectively and withstand temperatures typically encountered in cooking (up to 250-300°C or higher for oven-safe items). While durable, materials like aluminum can warp at very high temperatures, and some coatings can degrade.

- Tube Materials: For applications involving high temperatures (e.g., in chemical reactors, furnaces, or aerospace), materials like Inconel, Hastelloy, or ceramics are used. These materials are engineered to maintain their mechanical properties and structural integrity at temperatures far exceeding those encountered in culinary settings, often reaching well over 1000°C.

Surface Treatments Enhancing Functionality

Both pans and tubes benefit from surface treatments that augment their inherent properties and expand their utility. These treatments can improve non-stick characteristics, corrosion resistance, wear resistance, or thermal management.

- For Pans:

- Non-stick Coatings (e.g., PTFE, Ceramic): Applied to reduce food adhesion, making cooking and cleaning easier.

- Hard Anodizing: For aluminum pans, this process creates a harder, more durable, and corrosion-resistant surface.

- Seasoning (for Cast Iron): A polymerized layer of oil that provides a natural non-stick surface and protects against rust.

- For Tubes:

- Passivation: A chemical treatment, often for stainless steel, that removes free iron from the surface and forms a protective chromium oxide layer, significantly enhancing corrosion resistance.

- Polishing: Smooth surfaces reduce friction and the potential for material buildup or contamination, which is vital in fluid handling and sterile applications.

- Coatings (e.g., PVD, CVD): Specialized coatings can impart properties like extreme hardness, wear resistance, or chemical inertness to the tube surface, extending its lifespan and performance in harsh environments.

Identifying Misconceptions and Clarifying Terminology

While the terms “pan” and “tube” might seem straightforward, their application across different domains can lead to confusion. This section aims to demystify these potential overlaps and highlight why precise language is paramount.It is common for individuals to encounter situations where an object’s description seems to bridge the gap between culinary and technical contexts. Understanding that the classification of an object as a “pan” or a “tube” is fundamentally driven by its intended function and design is key to resolving these apparent discrepancies.

Addressing Terminology Overlap Between Kitchenware and Technical Components

The English language, rich in its flexibility, often allows for words to take on multiple meanings depending on the context. This can be particularly true for terms like “pan” and “tube,” which have distinct primary definitions but can sometimes be used in ways that superficially resemble each other. In the culinary world, a “pan” is unequivocally a cooking vessel. However, in other fields, the word “pan” might appear in compound terms or idiomatic expressions that do not relate to cooking.

Similarly, while a “tube” primarily refers to a hollow cylinder, the term can be used metaphorically or in specialized technical jargon in ways that might momentarily blur its common understanding. Recognizing these dualities prevents misinterpretations and ensures clear communication.

Reasons for Context-Dependent Classification

An object’s designation as a “pan” or a “tube” is not arbitrary but is intrinsically linked to its purpose and form. A cooking pan, regardless of its shape, is designed to hold and heat food. Its features, such as a flat bottom, often a handle, and sometimes sloping sides, are optimized for this culinary function. Conversely, a tube, whether for scientific or technical applications, is primarily designed to contain, direct, or transport substances, or to serve as a structural element.

Its defining characteristic is its hollow, cylindrical or prismatic shape, facilitating flow or providing a conduit. The material, dimensions, and specific design elements all serve this primary purpose.

Situations Requiring Precise Language

Clarity in terminology is not merely an academic exercise; it is crucial for safety, efficiency, and accuracy in various professional and practical settings.Consider the following scenarios where precision is vital:

- Engineering and Manufacturing: When specifying components for a fluid transfer system, referring to a “tube” is essential. Using the term “pan” in this context would be incorrect and could lead to the selection of entirely inappropriate parts, potentially causing system failure or safety hazards.

- Scientific Research: In a laboratory setting, a scientist might use a test tube for chemical reactions. If they were to ask for a “pan” for this purpose, it would cause immediate confusion, as a cooking pan has no place in such an experiment.

- Construction: When discussing structural elements, a “tube” might refer to a hollow steel beam. A “pan” in construction typically refers to a formwork used for pouring concrete, such as a concrete floor pan. The distinction is critical for material selection and structural integrity.

- Everyday Communication: Even in casual conversation, if someone asks for a “pan” to carry water, it’s likely they mean a basin or a bucket, not a frying pan. Conversely, if a chef asks for a specific type of “tube” for piping ingredients, they are not referring to a scientific apparatus.

Purpose Dictates Classification

The intended function of an object serves as the ultimate arbiter in classifying it as a “pan” or a “tube.” A deep, cylindrical metal container designed for baking bread, for instance, would be classified as a “bread pan” due to its culinary purpose, even though its shape might superficially resemble a short, wide tube. Conversely, a long, hollow metal cylinder used to channel exhaust gases from an engine is unequivocally a “tube,” irrespective of its material or diameter.

The design features, such as the presence of handles, non-stick coatings, or specific venting mechanisms, are all indicators of a pan’s culinary role. In contrast, features like standardized connection points, smooth internal surfaces for fluid dynamics, or specific material compositions for heat or pressure resistance point towards a tube’s technical or scientific application.

The Importance of Context in Interpretation

Understanding the context in which “pan” or “tube” is used is paramount to correctly interpreting its meaning. Without context, ambiguity can arise. For example, if one encounters the phrase “pan-like structure” in a geological report, it refers to a shape resembling a pan, not a cooking utensil. Similarly, a “vacuum tube” in electronics is a technical component, bearing no relation to kitchenware.

The meaning of a word is its use in language.

This famous quote by Ludwig Wittgenstein underscores the importance of context. When encountering these terms, consider:

- The setting: Is the discussion taking place in a kitchen, a laboratory, a factory, or a construction site?

- The surrounding vocabulary: What other words are used alongside “pan” or “tube”? Technical jargon, culinary terms, or general descriptive language will provide clues.

- The presumed activity: What is likely being done with the object in question? Cooking, transporting, reacting, or constructing?

By actively considering these contextual elements, one can confidently discern whether “pan” refers to a cooking vessel or something else entirely, and whether “tube” signifies a conduit or a different type of object.

Closing Notes

In essence, while both pans and tubes are essential tools in their respective domains, their divergence in form, material, and purpose is profound. By appreciating these core differences, we can approach their use with greater clarity and effectiveness, ensuring optimal results whether we are creating a culinary masterpiece or conducting a critical scientific experiment.